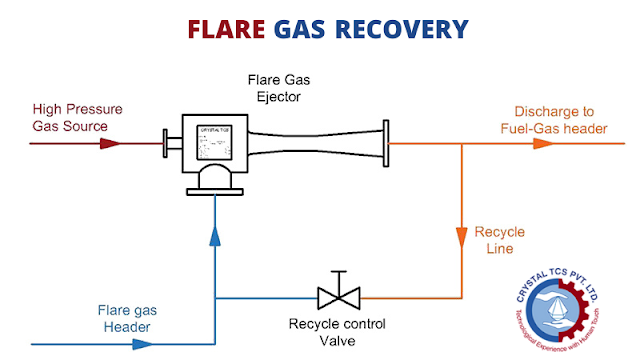

Ejectors perform a central role in Flare Gas Recovery Systems [subsequently denoted by FGRS] by compressing the low pressure gas mixtures to working pressures. Ejectors utilize the available high pressure gas as an energy source to bring about this compression.

Since the commencement of Oil and Gas Production and advent of petroleum refineries, little importance was given to the generated flare gas mixtures. This gas was termed as waste gas and was collected in large diameter headers. The gas was then burned off and the combustion products were let off to the Atmosphere. Flare Gas Recovery (FGR) is the process of recovering the waste gases that would normally be flared, so they can be used as fuel gas elsewhere in the facility. This results in reduced emissions and cost savings.

Flare Gas Handling Systems:

Since the commencement of Oil and Gas Production and the advent of petroleum refineries, little importance was given to the generated flare gas mixtures. This gas was termed as a waste gas and was collected in large diameter headers. The gas was then burned off and the combustion products were let off to the Atmosphere.

|

| Flare Gas Recovery |

Recovering and Reusing Flare Gas

An increasingly popular method is Flare Gas Recovery. Flare Gas Recovery is the process of recovering waste gases that would normally be flared. These gases are then used elsewhere in the facility, therefore reducing emissions and waste and consequently increasing efficiency.

Flare Gas Recovery System can be used in any industry that uses flaring. These include refining, production, LNG, biogas and pharmaceutical.

Criticality of Ejector Performance

The Ejector has to operate with a range of Motive Pressures and a range of Suction Flows. Ensuring a design that can satisfy a wide array of operating conditions in a Ejector is a critical task as Ejectors are single point devices.

In case of reduction of suction flow than the design value the Ejector may create vacuum in the flare header and the involved upstream equipment. The generated vacuum will disrupt the other processes and can also create mechanical damage. Hence in order to maintain the suction pressure a recycle line is used to recirculate flow form the discharge side to the suction side.

Matching the characteristics of the Recycle with the Ejector Characteristics is critical.

In case of higher than design suction flows the Ejector will not be able to provide the necessary compression, hence the relief valves on the suction side must be appropriately sized and matched with the Ejector operating characteristics.

In the case of a Multi-stage ejector system the criticality is further compounded.

Need for Flare Gas Recovery

- Flare Gas being a combination of petroleum gases can be used as a source of energy. An industrial survey has indicated that the amount of gas burned in the Flare Stacks throughout the world in the year 2011 amounted to almost USD 29.8 billion.

- Utilizing Flare gases helps the plant to cut down on its energy costs and also create an in-house Fuel source.

- Improper burning and incomplete burning leads to generation of toxic and harmful gaseous pollutants. The produced gases are known to create harmful and deadly effects on human life and the surrounding environment.

- The Flaring of Flare gas is also a considerable source of carbon di-oxide emissions.

- Hence utilizing flare gases can help an industry to reduce Energy costs, reduce its Carbon footprint and be responsible to the environment.

As stated above Flare Gas Recovery has to operate with a variable range of working conditions and compositions over their lifetime. We at Crystal TCS Pvt. Ltd have performed intensive research and development for coming with Ejectors in Flare Gas Recovery Systems.

Crystal TCS Pvt. Ltd.

Contact us: 02532501600

Comments

Post a Comment