One of the safe and pressure diminishing systems in oil and gas refineries, as well as petrochemical complexes, is the help header with the flare stack being the last segment. In this system, all the abundance gases are gathered and sent to flare stack to be burnt. A lot of these gas mixtures have a high warming quality and in some cases, it can even be used as the crude material for different units. It is clear that burning this gas mixture in flare stack causes environmental issues like air and noise pollution.

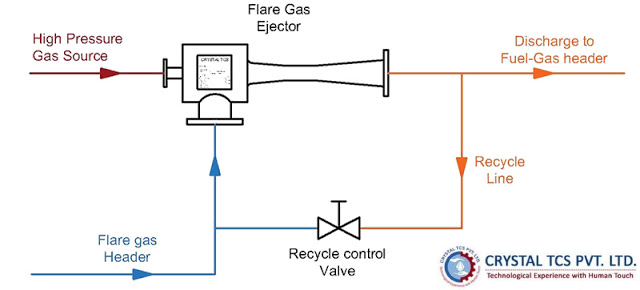

Flare Gas Recovery Systems are specialized compression bundles, which means to recover and repurpose gasses and emissions, like methane/LPG and sulfur dioxide that will usually be burned throughout the flaring method. Key to the protected operation of refineries and petrochemical facilities, the method involves capturing the gas from the flare knock-out vessel and pressures it using liquid ring compressors. The so-recovered gases may be reused inside the facility’s fuel facility, as a refinery feedstock or for reinfusion.

Advantages :

- Lower Emissions: Recovering waste hydrocarbons enables refineries to diminish the measure of poisonous gasses, for example, hydrogen sulfide (H2S), which are burned and discharged into the environment during the flaring procedure.

- Reduced Operating Costs: Refineries can re-utilize recovered gasses, made chiefly out of low atomic weight hydrocarbons (LPG), bringing about a decrease in fuel gas cost for the facility. This is, in addition, sparing that could be made because of decreased Greenhouse Gas emissions.

- Social and Environmental Responsibility: Lowering C02 emissions produced by facilities help organizations meet natural guidelines, yet in addition exhibit mindfulness and pledge to social obligation, and construct goodwill inside the encompassing network.

- Near zero flare emissions

- Improved community relations

- Recovered gas for facility fuel gas

- Reduced utility steam consumption

- Ease of installation

Crystal TCS’s expertise in Ejectors for Flare gas Recovery Systems

We at Crystal TCS has taken a theory-based approach towards establishing the Ejector performance estimation and have developed the design from the basic principles of Thermodynamics and Fluid flow dynamics. The developed theory and obtained algorithms have further been validated with rigorous performance evaluation tests at our Ejector test facility.

As stated above Flare Gas Ejectors have to operate with a variable range of working conditions and compositions over their lifetime. It is not possible to recreate each and every operating condition in the test facility.

Our theory-based approach has enabled us the flexibility to simulate each and every design case with the help of our algorithms and arrive at a precise and optimum solution. We manufacture Flare recovery systems in a wide range of materials ranging from Carbon Steel, Stainless Steels and Hastelloy depending upon the application.

Comments

Post a Comment